Payment Type:L/C,T/T,D/P,D/A,Paypal,Others

Min. Order:1 kg

Transportation:Ocean,Land,Air,Express,Others

$5000≥1Others

Place Of Origin: China

Status: New

Warranty Period: 1 Year

Applicable Industry: Machinery Repair Shops, Retail, Construction Works, Other

Where To Provide Local Services (in Which Countries Are There Overseas Service Outlets): Egypt, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines

Video Factory Inspection: Provided

Mechanical Test Report: Provided

Marketing Type: New Product 2020

Core Component Warranty Period: 1 Year

Core Components: Engine, Pump

Electric Power Models:: 5800*1800*1900mm

Diesel Power Models:: 6200*1800*2000mm

Electric Power Model:: 5000KG

Diesel Power Model:: 5800KG

Transportation: Ocean,Land,Air,Express,Others

Payment Type: L/C,T/T,D/P,D/A,Paypal,Others

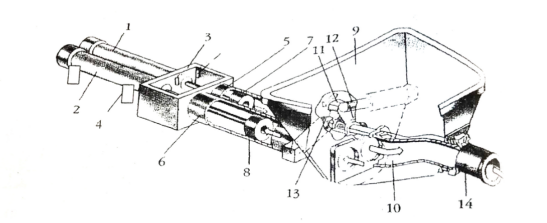

| Concrete Pump pumping principle This machine uses AC motor as the driving power source, the hydraulic system adopts open oil circuit, constant power control, and the concrete delivery volume has the function of stepless adjustment. The pumping system is shown in Figure 5. The pumping system mainly consists of two pumping cylinders 1 and 2, a water tank 3, a reversing device 4, two concrete cylinders 5 and 6, two concrete cylinder pistons 7 and 8, a hopper 9, and a distribution valve 10 (also known as S pipe). ), rocker arm 11, two swing cylinders 12, 13, etc. 1. Pumping cylinder 2. Pumping cylinder 3. Water tank 4. Reversing device 5. Concrete cylinder 6. Concrete cylinder 7. Concrete piston 8. Concrete piston9. Hopper 10. S pipe valve 11. Rocker arm 12. Swing cylinder 13. Swing cylinder 14. Discharge port The concrete cylinder pistons (7, 8) are respectively connected with the piston rods of the pumping cylinders (1, 2), and the two cylinders 1, 2 are connected in series to reciprocate under the action of the hydraulic oil of the pumping cylinders. One cylinder piston advances, the other cylinder piston retreats. The outlet of the concrete cylinder is communicated with the hopper. One end of the distribution valve 10 is communicated with the discharge port 14 of the hopper 9; the other end is communicated with the concrete cylinder 5 or 6. The spline shaft on the distribution valve 10 is linked with the rocker arm. Under the action of the swinging oil cylinders 12 and 13, the distribution valve 10 can swing left and right and communicate with the concrete cylinders (5, 6) alternately. When pumping concrete, under the action of the pumping cylinder, the concrete piston 7 is pushed forward, and the concrete in the concrete cylinder 5 is pushed into the distribution valve 10 and into the discharge port 15 (at this time, the distribution valve 10 is connected to the concrete cylinder 5. At the same time, the concrete piston 8 runs backward, and the concrete material in the hopper 9 is sucked into the cylinder 6. When the concrete piston 8 retreats to the end of the stroke, the hydraulic control check valve 4 on the pumping cylinder is opened (refer to the hydraulic principle diagram), and the control oil flows from the hydraulic control check valve to the hydraulic control two-position four-way valve to change the valve. Towards. Swing the oil cylinder (12, 13), so that the distribution valve 10 is connected with the concrete cylinder 6, and the concrete cylinder 5 is connected with the hopper. At this time, the high-pressure oil of the system is passed through the swinging oil cylinder to change the direction of the two-position four-way valve (refer to the hydraulic principle diagram), so The piston 7 retreats and sucks concrete from the hopper, and the piston 8 moves forward to push the concrete in the concrete cylinder into the S valve and the conveying pipeline. This cycle enables continuous pumping (see Figure 6). When the pump is reversed, the "reverse pump" button is operated to make the concrete cylinder in the suction stroke communicate with the distribution valve, and the concrete cylinder in the push stroke to communicate with the hopper, so that the concrete in the pipeline is pumped back to the concrete cylinder 5, The concrete in the cylinder 6 is pressed back into the hopper 9 (see Figure 7). |

Our company produces Power Trowel , which is divided into ride-on power trowel, double pan power trowel, etc. It also produces Road marking machine, which is divided into Thermoplastic Road Marking Machine, road line mark machine, etc. But one of our hot selling products is mini excavator.

Our company's Mini Excavator is divided into Mini Crawler Excavator,Mini Rubber Excavator and Mini Hydraulic Excavator.